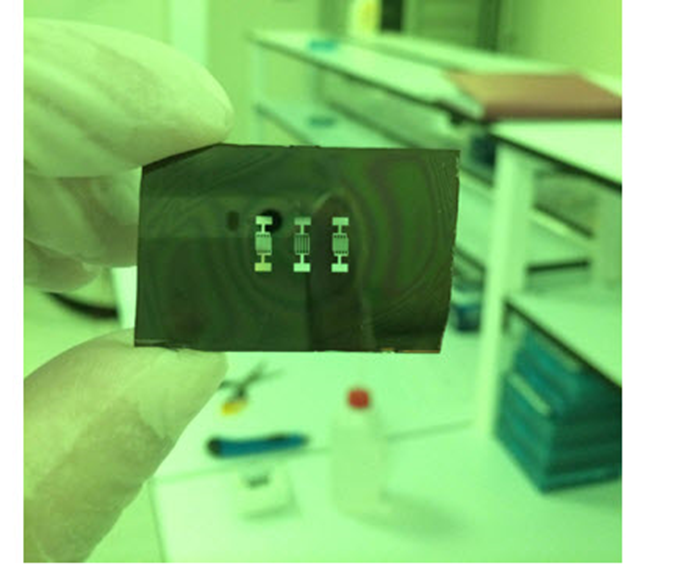

During my M.S thesis we have produced unidirectional surface acoustic wave sensor (UDT SAW). In nano-technology lab there is cleanroom where device of micro or nano size can be fabricated. Cleanroom is needed for avoiding dust and other not visible to human particles from fabrication process. Because dust or even very tiny particles can damage fabrication process and all process should be repeated. That’s why while working in clean room there are rules should be obeyed, for example special type of wearing should be weared to avoid dust and other small particles. During fabrication different type of machines were used, which are: photolithography, reactive ion etching machine, and DC sputtering machine.

Lithography Machine

Reactive Etching Machine

Sputter Machine

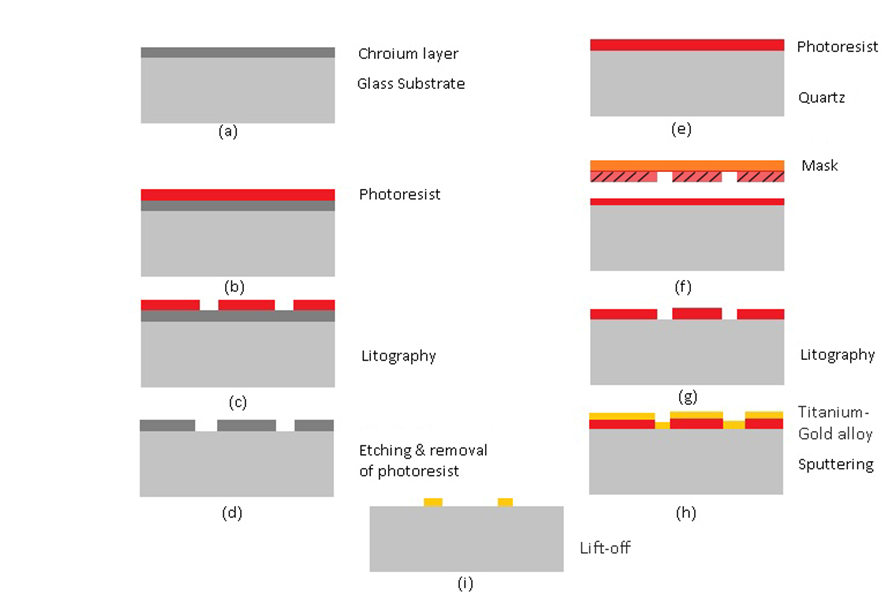

Fabrication took 4 steps or 4 days. Each day about 1 hour was wasted. So, average fabrication time is about 5-6 hours.In next figure, preparation of mask and fabrication of UDT IDT are shown step by step. For preparation of mask we are used chromium glass and photoresist. For fabrication; titanium-gold alloy, photoresist and quartz

Step by step Fabrication Process